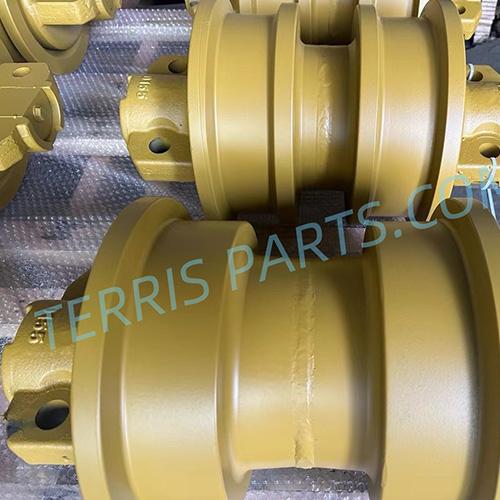

Track Roller

- Professional design and manufacturing of track roller

- Competitive prices

- Support extremely cold and hot working conditions

- Over 500 models of track rollers are available for all brands

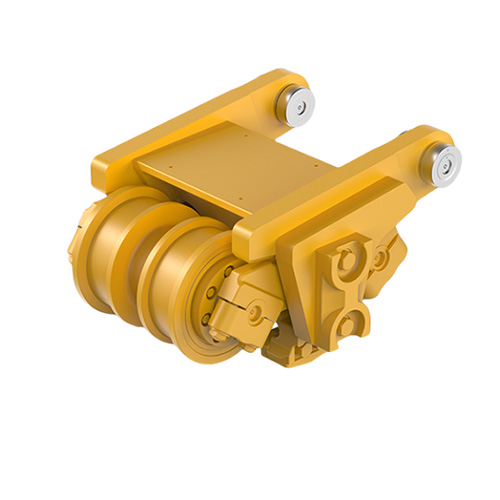

- Supports single flange and double flange bulldozer track rollers ranging from 130 to 290mm

- Support excavator track rollers with rail surface diameters ranging from 100 to 285mm

Characteristics of Track Roller

Terris uses a wheel body that has undergone overall quenching treatment, combined with certified floating sealing technology. Ensure the reliability of the product under harsh working conditions of extreme cold or heat through extreme mining overload testing. Effectively improve durability and stability.

Terris Track Roller Craftsmanship

Track roller body: made of high hardenability alloy steel, forged and quenched as a whole to improve the strength and surface wear resistance of the wheel body;

Shaft: Made of high-quality alloy steel, surface quenched and tempered, and polished after grinding the sliding working surface to achieve effective surface roughness and control temperature rise during operation;

Shaft bushing: The wheel system product of large tonnage excavators uses high-strength brass shaft sleeves to enhance the load-bearing capacity of the wheels;

Shaft seat: made of high-strength ductile iron or cast steel material, formed by precision casting, and ground after precision machining of the thrust surface to obtain good surface roughness, reduce working temperature and wear;

Floating oil seal: Designed with high wear resistant floating seal ring material, the grinding working surface is finely ground and polished. After hardness and strength testing, the floating seal rubber ring is subjected to high-temperature aging and compression deformation tests to ensure that all technical indicators of the rubber ring meet the adaptability requirements of working conditions;

Oil product: Select oil products according to the actual working conditions of the host to meet various complex working conditions such as extreme cold and high temperature.

Supply Range

Undercarriage parts for excavators with a pitch ranging from 90mm to 317mm and bulldozers with a pitch ranging from 135mm to 317mm

KOMATSU Track Roller

KOMATSU Track Roller CATERPILLAR Track Roller

CATERPILLAR Track Roller HITACHI Track Roller

HITACHI Track Roller VOLVO Track Roller

VOLVO Track Roller LIEBHERR Track Roller

LIEBHERR Track Roller KOBELCO Track Roller

KOBELCO Track Roller DOOSAN Track Roller

DOOSAN Track Roller LiuGong Track Roller

LiuGong Track Roller SDLG Track Roller

SDLG Track Roller SANY Track Roller

SANY Track Roller XCMG Track Roller

XCMG Track Roller HYUNDAI Track Roller

HYUNDAI Track Roller SUMITOMO Track Roller

SUMITOMO Track Roller

Why choose Terris?

It is the first in China to create a multi-body dynamics model for crawler chassis, integrating DOE simulation/rigid-flexible coupling/meta-analysis technology, and providing full working condition analysis. Master the core design of the floating oil seal for the track roller, build a simulation test platform, and the product verification capability is internationally leading.

Possessing hot-die forging + simulation technology to produce high-precision forgings; Special alloy steel + intelligent heat treatment to enhance performance; Online monitoring + tool compensation ensures precise machining; Fully automatic assembly + real-time monitoring to ensure quality, adaptable to multiple working conditions.

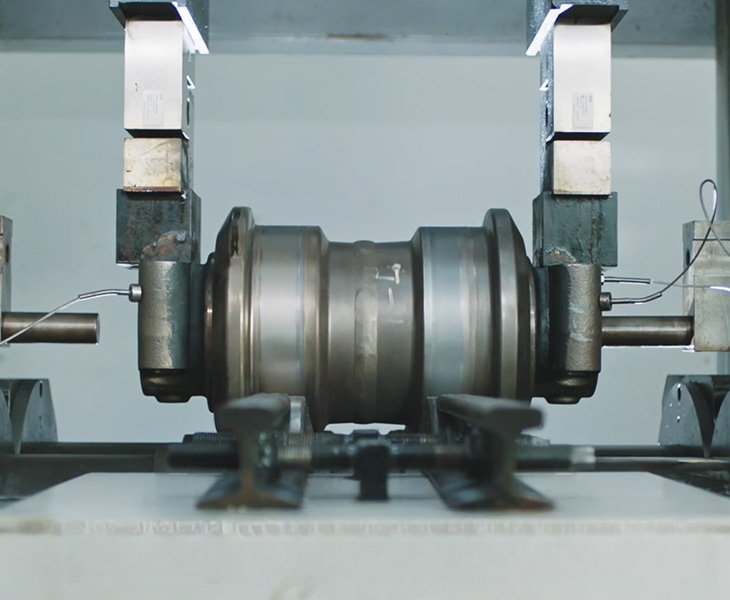

Establish physical and chemical/mechanical/reliability laboratories, equipped with spectrometers and other devices; Our professional quality inspection team conducts a full inspection of the raw material composition/structure and the microscopic/mechanical properties after the manufacturing process, providing double guarantees for quality compliance.

We focus on global high-end OEM mainframe support and are committed to providing complete solutions for the aftermarket of large-tonnage mining equipment. This includes brands such as LIEBHERR, HITACHI, and HYUNDAI.

Digitize and develop high-end process equipment to build a safe, efficient and intelligent cluster. Flexible lines cover the entire process of hot-die forging, heat treatment, welding, etc., integrate intelligent equipment, and build a stable and traceable intelligent manufacturing system.

Supports all working conditions, all weather conditions, OEM, large tonnage, full set customization. The development cycle from product design, testing to verification is 45-60 days.

Production Process

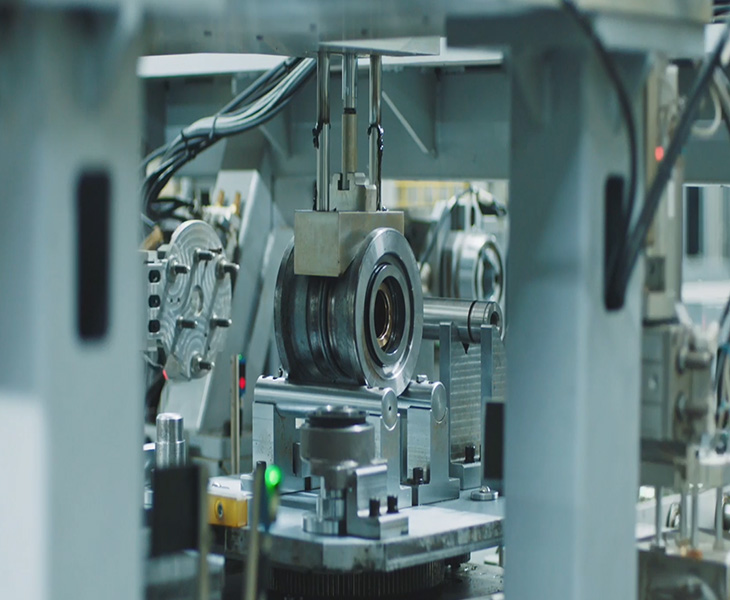

Terris researches and develops high-end process equipment in a digital way to create a manufacturing cluster with safe operation, high efficiency, and intelligence. Flexibility, stable processes, reliable products, and strong traceability. A flexible processing line for the entire product process, covering the entire process of hot-die forging/heat treatment/welding, including the world’s advanced fully automatic hot-die forging, fully automatic heat treatment and welding, fully automatic track and wheel combination.

Research and Development Technology Platform

Innovatively constructing a multi-body dynamic model of excavator track chain, combining full condition simulation and rigid flexible coupling technology to achieve stress analysis of components throughout their lifecycle, and developing high-precision parameterized stress models; At the same time, mastering the core design technology of floating seals for supporting wheels and establishing an internationally leading simulation test system can quickly verify the performance and reliability of wheel system products under extreme loads, forming a complete technical loop from theoretical modeling to actual testing verification.

Advanced Production Technology

integrating fully automatic hot-die forging, special alloy material development, intelligent processing and assembly technology: achieving high-precision forging manufacturing through forging simulation and intelligent monitoring, innovating special steel formula matching exclusive heat treatment to enhance component wear resistance and strength; By applying online monitoring and tool compensation technology to ensure machining accuracy, combined with real-time perception of key parameters on fully automated assembly lines, forming an intelligent process closed-loop covering the entire forging processing assembly chain, achieving a dual breakthrough in product performance and quality.

Quality Assurance Capability

Terris has established a full process quality inspection system covering raw materials to finished products. Relying on physical and chemical analysis, mechanical properties, and reliability laboratories, it is equipped with precision equipment such as direct reading spectrometers and end quenching testing machines, and has formed a professional quality inspection team to achieve comprehensive testing of 23 indicators such as raw material chemical composition, microstructure, and hardenability; Through process monitoring methods such as microstructure analysis and mechanical property testing, the quality of key processes such as forging/heat treatment is verified throughout the entire process, forming a closed-loop quality control network from raw material entry to product delivery, ensuring accurate matching between material properties and process parameters.