Our Team

Our Guarantee Capability

Terris establishes physical and chemical analysis, mechanical performance analysis, and reliability laboratories; Establish a quality control team led by inspection technical engineers, with various experimenters as the backbone and a complete professional structure; Configure a direct reading spectrometer, end quenching testing machine, metallographic microscope, and a complete set of mechanical performance testing machines. It can achieve comprehensive inspection and analysis of raw material chemical composition, macrostructure, non-metallic inclusions, grain size, end hardenability, hairline, and other aspects to ensure the quality of raw materials; Conduct a comprehensive inspection of the microstructure, mechanical properties, shear and bending strength of materials after forging, heat treatment and other heat processing to ensure product performance compliance.We are committed to building a world-class mining service brand and providing full life cycle service solutions for your mining equipment.

Intelligent Manufacturing Operation Platform

- We have intelligent production line robots and intelligent process equipment. We research and develop high-end process equipment directly and digitally to create an intelligent manufacturing cluster with safe operation, high efficiency and flexibility, stable process, reliable products and strong traceability.

- We have more than full-process product flexible processing lines, including the world’s advanced automatic hot die forging, fully automatic heat treatment and welding, fully automatic crawler and wheel assembly.

- About quality Assurance, we have comprehensive equipment for monitoring raw material composition and microinstruction, as well as for testing heat treatment paleography and mechanical properties. this allows us to implement standardized quality control throughout the whole process, ROM raw materials to manufacturing product warehousing and shipping.

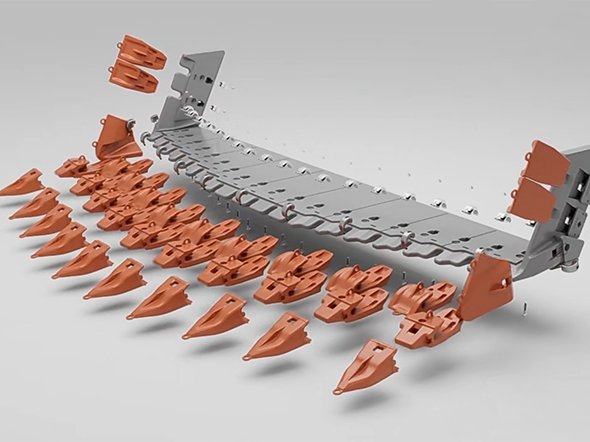

Bucket teeth and Adapters

- Currently, there are more than 3,000 products, so far we already develop with the smallest product being 0.3 kg and the largest being 600 kg.

- We have 6 engineers with more than 20 years of forging and casting experience, as well as advanced heat treatment equipment, which can achieve high hardness and good impact toughness of products. The surface hardness and core hardness of products within 30 kg are within ±1.5 HRC, and the surface hardness and core hardness of products within 70 kg are within ±3 HRC. T1 material hardness is 48-51HRC, impact>16J, T2 material hardness is 49-53HRC, impact>18J, T3 material hardness is 50-54HRC, impact>20J.

- Terris has precision casting and forging technology, coated sand technology, resin sand technology, and Negative pressure solid mold casting to meet the production of various sizes of products.

- Annual output is currently 15,000 tons. It is exported to more than 60 countries overseas.

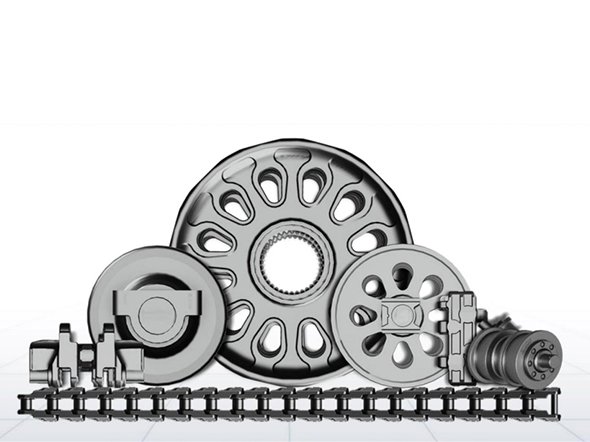

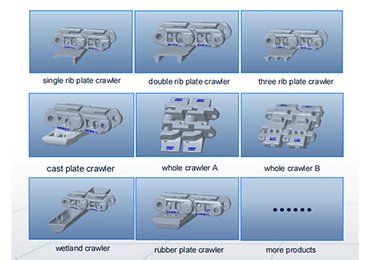

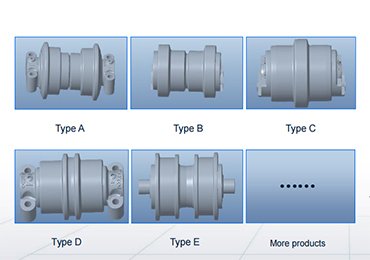

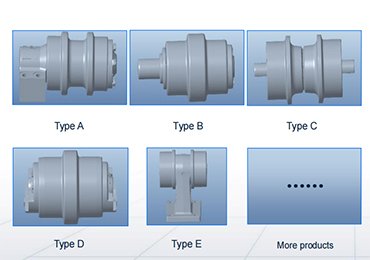

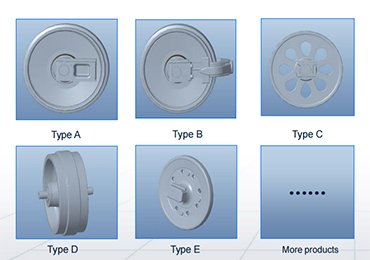

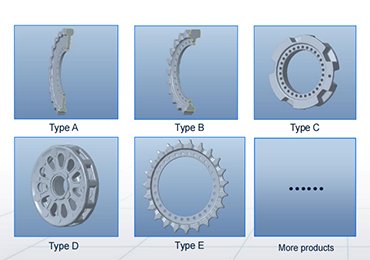

Undercarriage Parts

Ground Engaging Tools