Caterpillar Idler

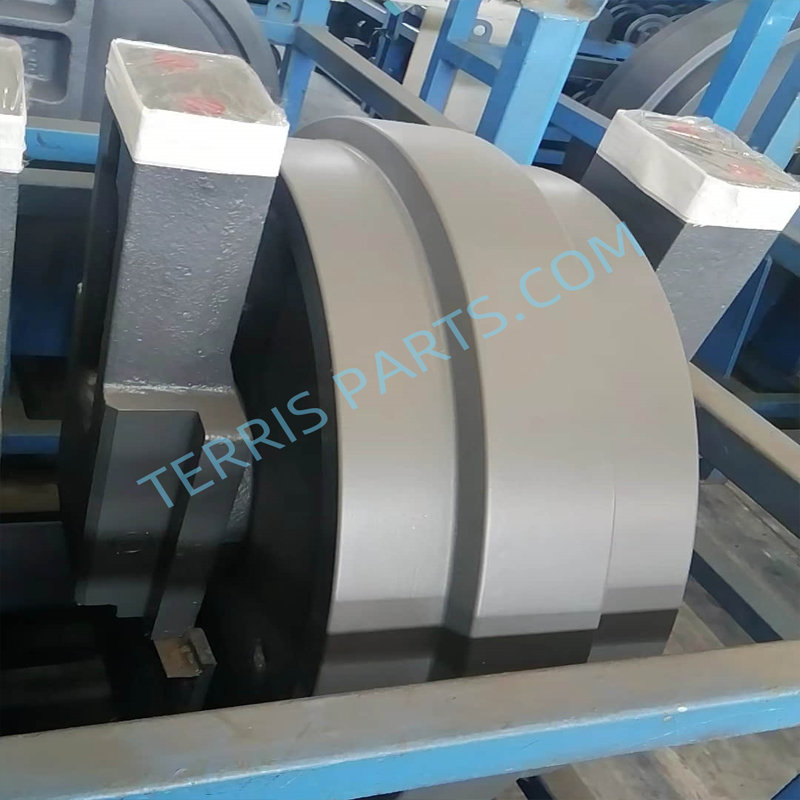

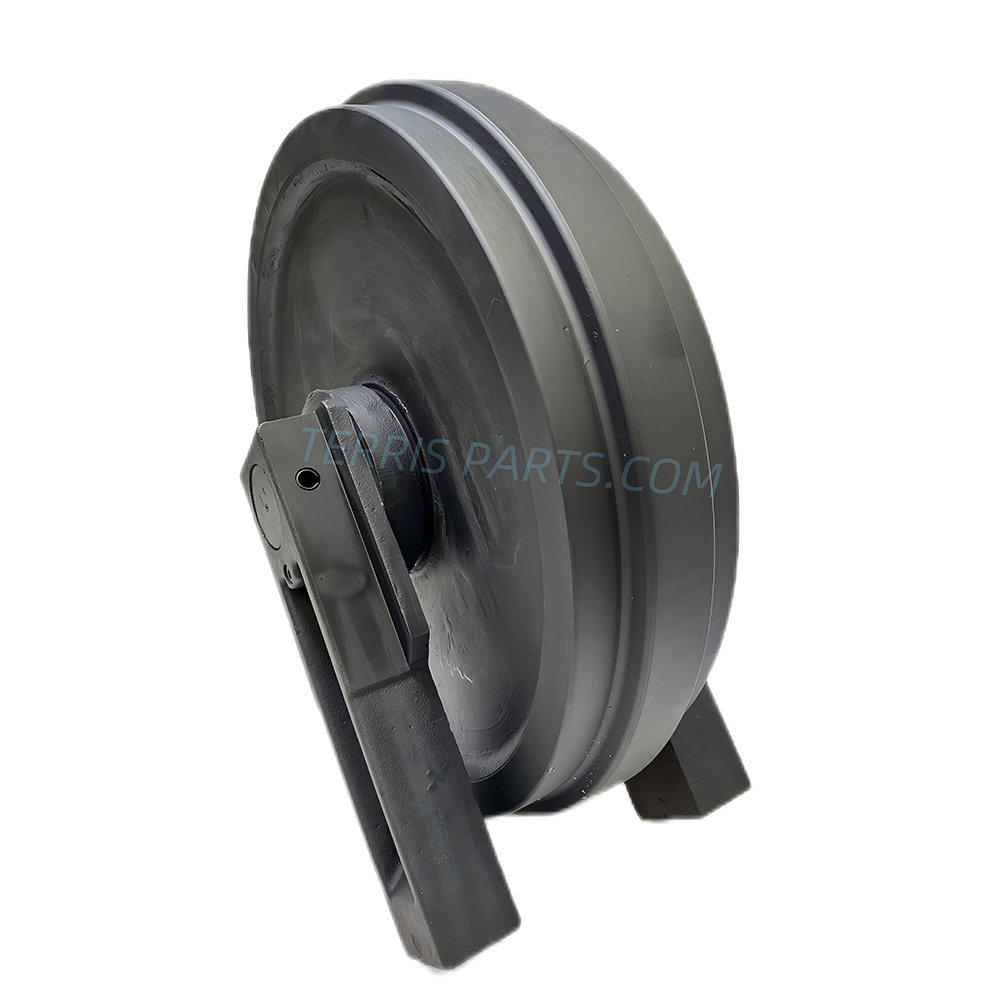

The Caterpillar idler, like its name, has the function of guiding and steering. In the equipment for steering, the spring assembly of the chassis system will control the operation of the idler, in order to avoid the idler can’t work properly. After the equipment stops, you should clean up the accumulation of soil and bits on the idler, to avoid entering into the internal bearings, in the equipment up and down the slope should be avoided to guide the wheel towards the back, this is easy to let the chain derailment. The wheel body of Caterpillar idler adopts a roller forging process, the wheel surface is tough enough after long time of forging, and the wheel axle is treated with high accuracy, basically not much need to replace this part. And the use of a lightweight design, the overall performance of the equipment have been significantly improved, and lower the transportation costs.

Terris Caterpillar idlers are designed with reference to a number of manufacturers’ processes to create a product that is unique to Terris. After roll forging the wheel body, we apply a specific process to the track surface of the Caterpillar idler, which solves a series of problems such as wheel surface collapse, wheel surface cracking, etc., and prolongs the service life of the wheel. For the treatment of axle, bushing and bracket, we have also made a lot of technical research and development improvements through the study of the characteristics of Caterpillar’s idler, and then produced reliable products that do not leak oil, do not break the axle, and are wear-resistant and durable! We have been recognized by the OEMS of the host equipment manufacturers in the industry for our quality control.

If you have any ideas about Caterpillar idler in the use of equipment, welcome to contact our product manager, our design and development team to discuss, consult Terris, find the right for your equipment, get a quick quote for various models of Caterpillar idler or provide us with valuable suggestions for our products!

Product By Models

Date:MAX OD:380MM

Part number:240-6304

Suitable To:CAT E305 E306E E306 E306E2 E305.5E2 E305.5E

Date:MAX OD:450MM

Part number:115-6335, 277-8668

Suitable To:CAT E307C, E307B

Date:MAX OD:450MM

Part number:277-8667,

Suitable To:CAT E307E, E307D, E308C

Date:MAX OD:486MM

Part number:4I7337

Suitable To:CAT E311, E312D, E314C, E314E

Date:MAX OD:540MM

Part number:102-8151

Suitable To:CAT E315, E318C, E320B, E320D, E323D

Date:MAX OD:540MM

Part number:115-6337

Suitable To:CAT 322B, E322C, E324D

Date:MAX OD:575MM

Part number:102-8149

Suitable To:CAT E325D, E325B

Date:MAX OD:680MM

Part number:102-8152

Suitable To:CAT E330B, E330C, E330D, E336D, E336E

Date:MAX OD:680MM

Part number:115-6366

Suitable To:CAT E345B, E345D, E349D, E349E

Date:MAX OD:775MM

Part number:136-2429

Suitable To:CAT E345B, E345C, E365B, E365C

Date:MAX OD:775MM

Part number:567-7852

Suitable To:CAT E365CL, E374D, E374F, E385C

Date:MAX OD:815MM

Part number:567-7867

Suitable To:CAT E390D, E390F, E395, E385C