The excavator track shoes is a component of the excavator body that directly contacts the ground, carrying the weight of the entire equipment. It disperses the load of the equipment through a large area of contact with the ground, allowing the weight of the equipment itself and the pressure of the load to be evenly distributed on the ground.

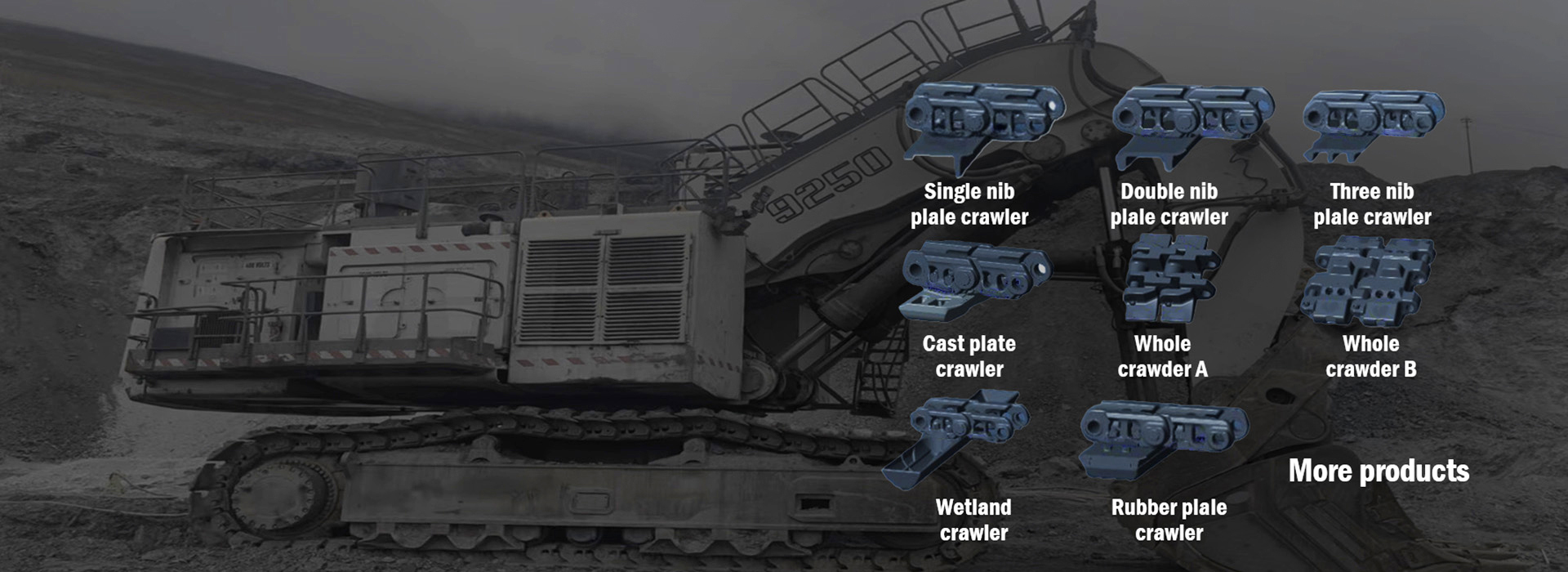

Terris factory has over 13 years of experience in manufacturing track chassis systems. The common excavator track shoes has three or two gripping teeth, and Terris has thousands of designs to cope with different complex working conditions. Design excavator track shoes for 0.8-800 ton equipment for brands such as Komatsu, Caterpillar, Volvo, Hitachi, Hyundai, and Liebherr. In order to adapt to various working environments such as wetlands, logging, earthwork construction, quarrying and mining, Terris has designed excavator track shoes with various structures. They can keep the equipment unobstructed and protect the equipment body and chassis system in different complex terrains. Adopting precision casting technology for large equipment. Terris has developed high-strength special wear-resistant steel as the main material. After surface strengthening heat treatment, the overall hardness reaches HCR35-50 Rockwell degree. While considering hardness, toughness treatment is also essential to form excavator track shoes that are compressive, wear-resistant, impact resistant, and not easy to break. In high wear environments, we can also weld high wear-resistant tungsten carbide on the ground contact gripping teeth to increase the wear-resistant layer and improve wear resistance.

What are the working environment requirements for your excavator track shoes? Contact us for a quick quote.

Our Products